At Green Booth, we provide a range of spray booth designs tailored to the unique requirements of the automotive and industrial painting sectors. Our booths are organised into categories based on the type of paint they use, the airflow technology they employ, and any additional features they include. This clear organisation makes it easier for our customers to select the ideal booth for their specific needs.

spray BooTh Paint Type

Water-Based Paint Booths:

- Eco-Friendly: Designed to use water-based paints which emit fewer volatile organic compounds (VOCs), making them safer for the environment and the workplace.

- High-Quality Finish: Engineered to optimize the application and drying of water-based paints to achieve a flawless finish with reduced environmental impact.

Tap the image to view it in full size.

Water Based Booth SPECIFICATIONS

Solvent-Based Paint Booths:

- High Performance: Ideal for solvent-based paints, known for their durability and faster drying times. These booths handle the more volatile compounds efficiently, ensuring safety and quality.

- Superior Durability: Provides a robust application that is perfect for achieving a smooth and lasting finish on a variety of surfaces.

Tap the image to view it in full size.

Spray Booth Design and Airflow Technology

Single Panel Enclosed Downdraft Spray booth:

- Standard Single Panel Enclosed Downdraft:

Description: This basic model provides efficient airflow by drawing air downwards, effectively capturing overspray. - Single Panel Enclosed Downdraft with Infrared Heater and Rear Back Door:

Enhancements: Features an infrared heater to accelerate the drying process and a rear back door for better access and improved workflow. - Single Panel Enclosed Downdraft with Metal Basement and Infrared Heater (2 Row Grating):

Advanced Features: Equipped with a robust metal basement for additional support and an infrared heater integrated within a two-row grating for uniform heat distribution.

Tap the image to view it in full size.

Single Panel Enclosed Air Suction Spray booth:

Airflow Design: Employs a unique airflow method where air is drawn across the panel from one side to the other, aiding in the removal of overspray and maintaining a clean workspace.

Tap the image to view it in full size.

Double Panel Enclosed Downdraft Spray Booths

- Standard Models:

- With Diesel Burner & Full Grating Civil Basement: This model includes a diesel burner for heating and a full grating over a civil basement for superior airflow and strength.

- With Metal Basement: Provides a sturdy metal basement, enhancing the durability and stability of the booth structure.

Tap the image to view it in full size.

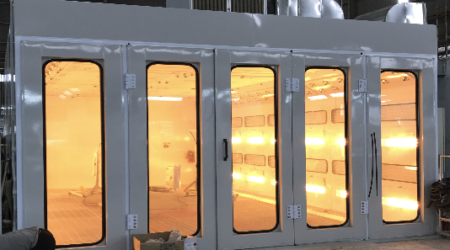

2. Infrared Heater Models:

- With Infrared Heater & Metal Basement Full Grating: Features an infrared heater for faster drying and curing, coupled with a full metal basement grating for enhanced airflow.

- With Infrared Heater (Full Grating): Includes an infrared heater integrated into a full grating setup, optimizing heat distribution and curing efficiency.

- With Infrared Heater (2 Row Grating): This configuration uses an infrared heater with a two-row grating system, designed to focus the heating effect more efficiently across multiple zones.

Tap the image to view it in full size.