SANDBLASTING BOOTH

At Green Booth, we specialise in designing and manufacturing high-quality sandblasting booths and rooms tailored to meet the demands of various industries. Our sandblasting solutions are built with advanced technology, ensuring superior performance, safety, and durability. Whether you’re working in automotive, aerospace, or manufacturing, our booths are customizable to fit any space or specific requirement.

Our expertise in creating efficient and safe sandblasting environments is showcased through the precision of our designs. We offer high-tech ventilation systems, easy-to-use control panels, and customizable options that suit your unique needs. Check out the images below to see the superior build quality and features of our sandblasting booths and rooms in action

A Sandblasting room consist of an enclosure that prevents abrasive material from entering the outside air and has a system designed to reclaim your abrasive material. After the leftover abrasive is recovered, it is then moved to a recovery system that will separate the dust from the leftover abrasive so that the high-quality abrasive can be reused again.

Sandblasting is an operation of forcibly propelling a stream of abrasive material against a surface under high pressure to smooth a rough surface or to remove surface contaminants.

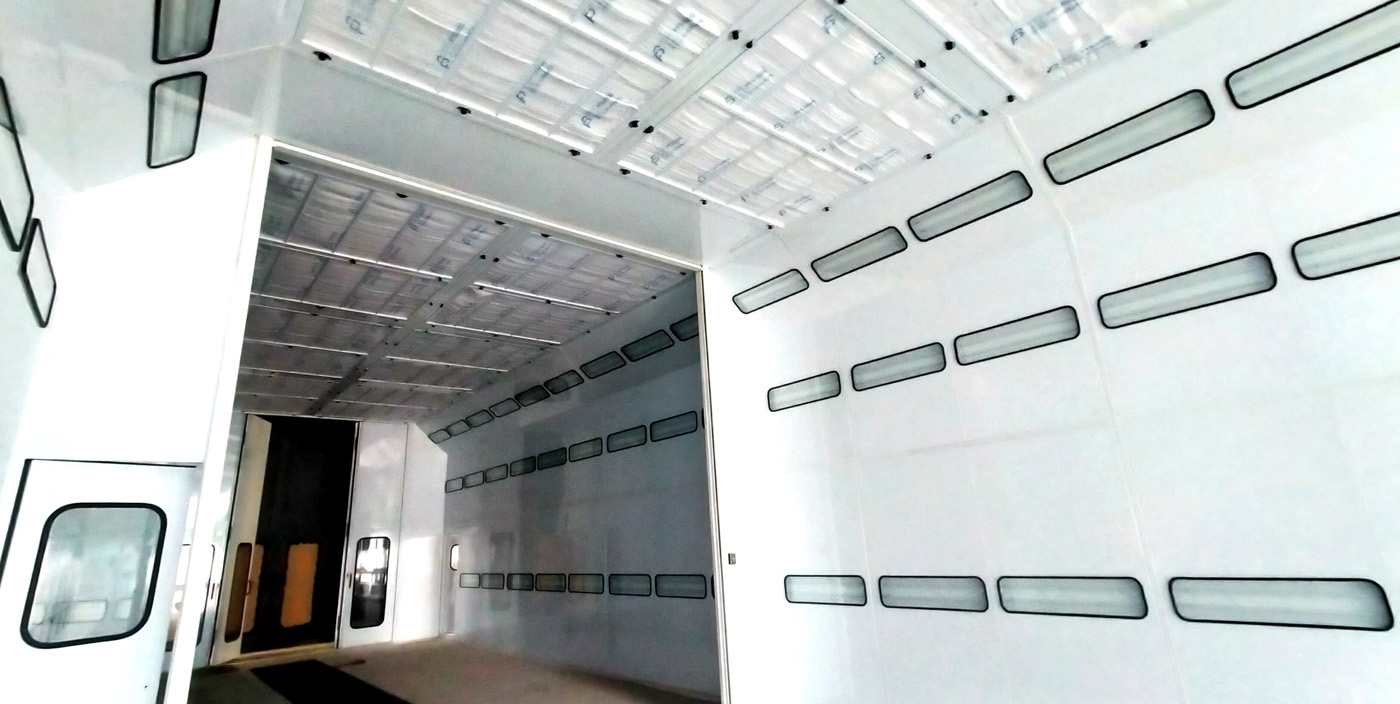

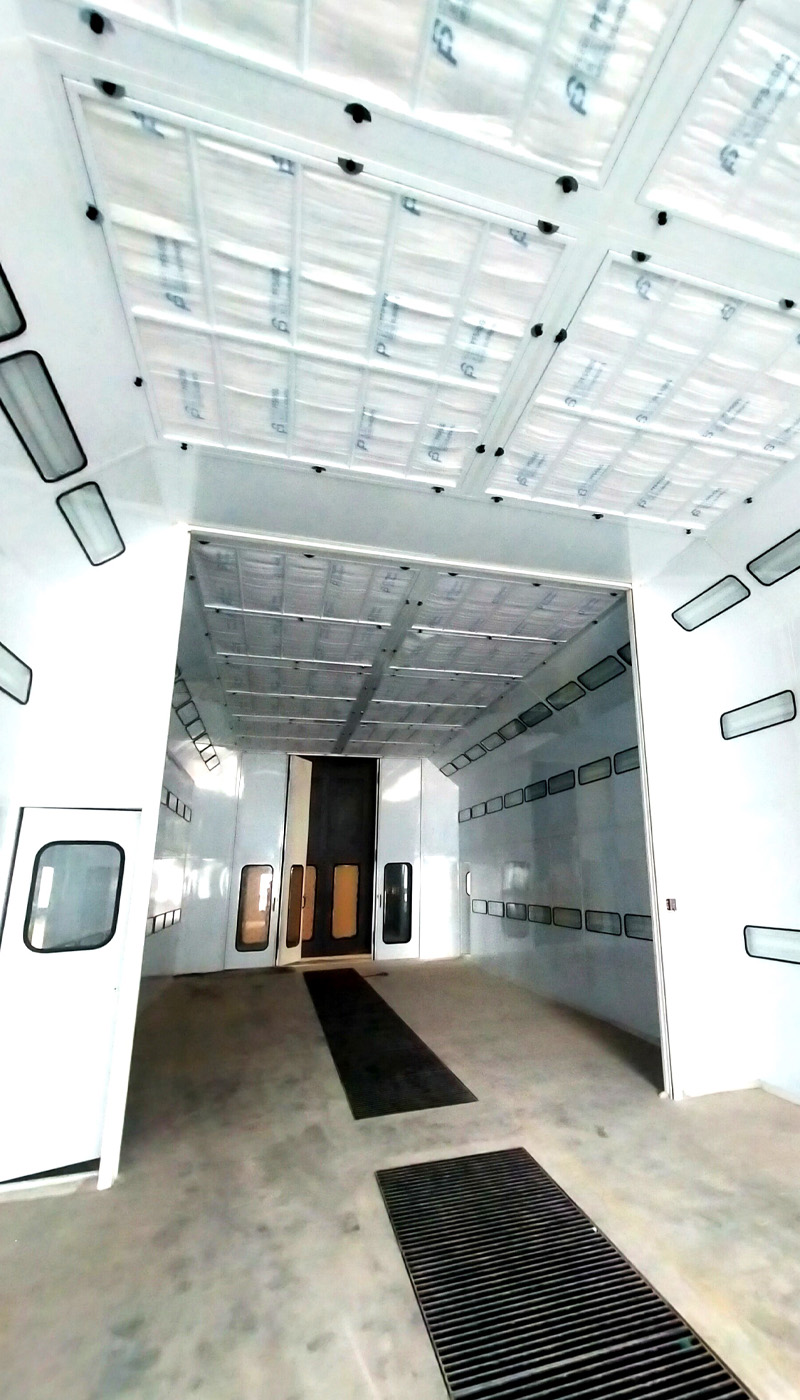

Front view of a sandblasting booth, with large doors for equipment entry. The robust design ensures durability and efficient containment of blasting materials

Sand blasting booth with curtain enclosures, designed to prevent dust and debris from escaping while allowing easy access for loading and unloading

Interior of a sandblasting booth, equipped with a high ceiling, exhaust systems, and ample lighting. The design ensures proper airflow and visibility during operations, providing a safe and efficient blasting environment

Dust extraction and filtration system indoor (the filtration unit and inlets) to outdoor (the large dust collectors and exhaust system). This provides a full view of how dust is managed both inside and outside of the facility, ensuring clean air circulation during sand blasting operations.

Drive mechanism or motor of an industrial sand blasting machine, with safety warnings and labels indicating regular maintenance requirements for optimal performance.

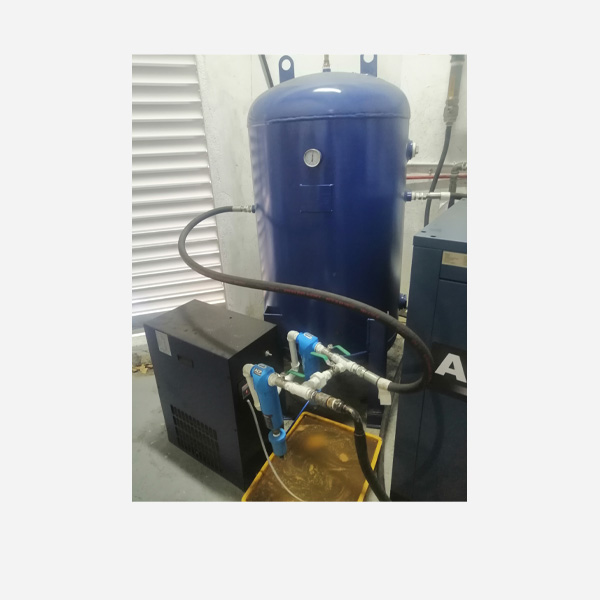

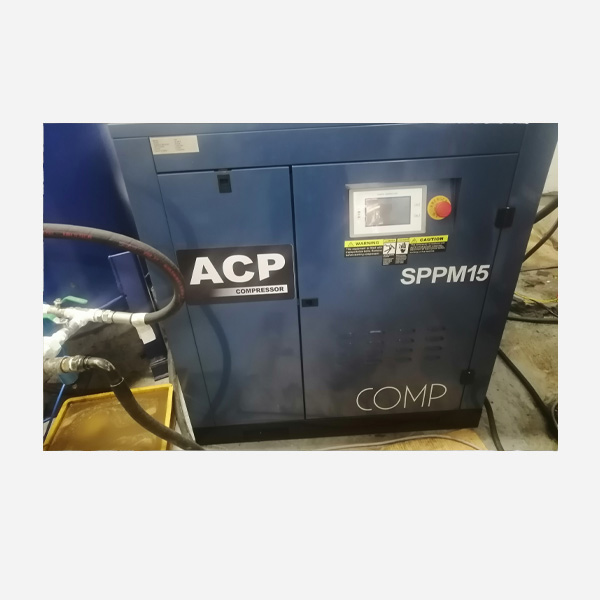

Compressed air system used to power the sand blasting operations. The blue air compressor and tanks provide the necessary air pressure for the blasting process, essential for effective surface cleaning and preparation

Control panel for the sandblasting system, featuring various operational buttons and indicators that allow operators to manage airflow, pressure, and other key functions.